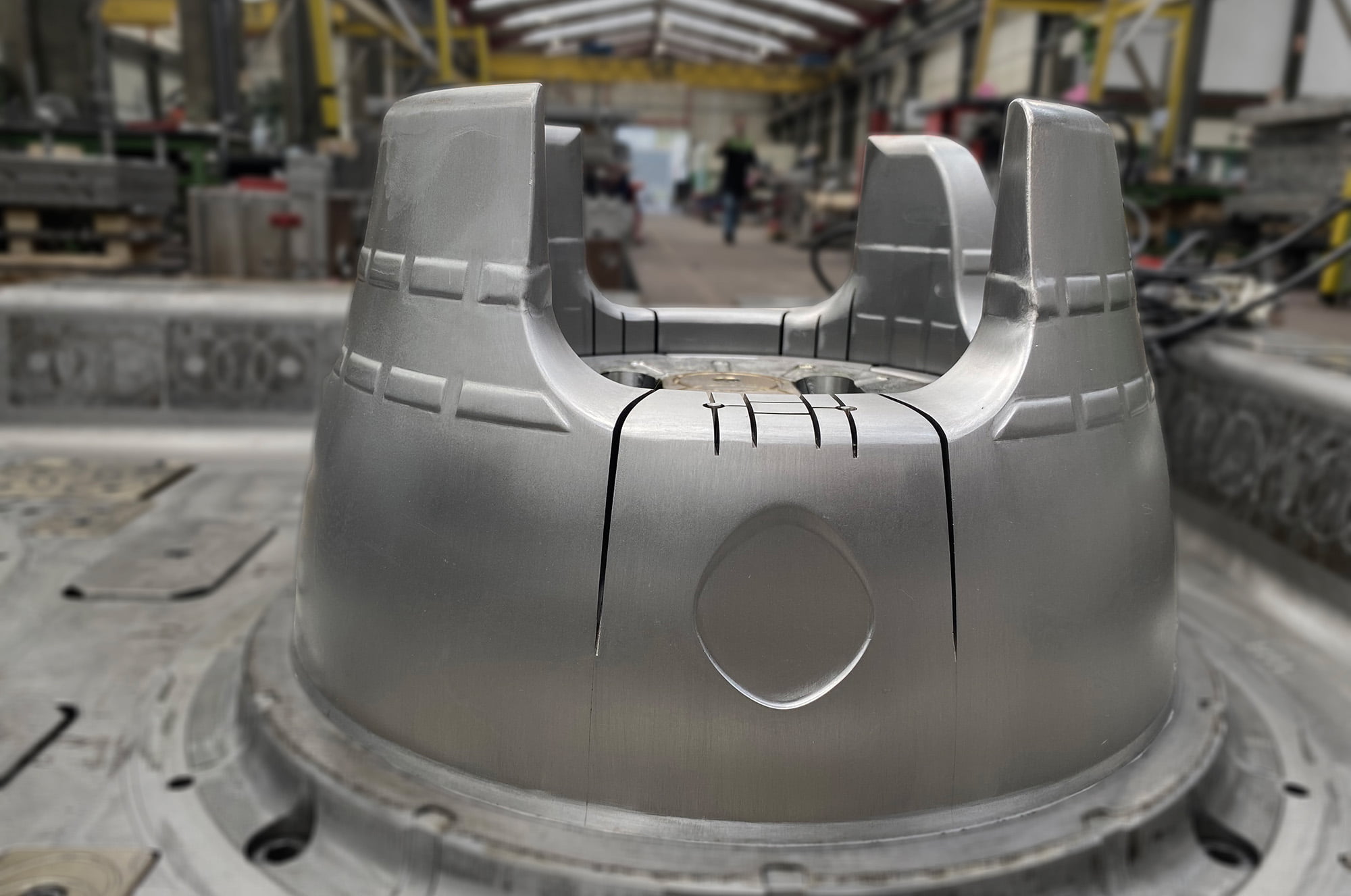

It is essential that companies invest in efficiency in a structured way. Optimizing production processes, reducing waste and implementing new technologies are fundamental actions to face the challenges ahead.

The mold industry is currently facing significant challenges, with a shrinking market and delicate economic conditions for many companies. However, it is possible to glimpse a promising future if there is a transformation of the management mindset, a structured investment in efficiency, a commitment to innovation and global competitiveness, close collaboration between companies, educational and research institutions and government entities. With these actions, the mold industry will be able to resume its growth and contribute to the country's economic development.

Despite the challenges that the mold industry has been facing, there are also great opportunities for the future.

To take full advantage of these opportunities, companies need to be agile, flexible and able to adapt quickly to market changes. Optimizing production processes, reducing waste and implementing new technologies are also fundamental actions to meet the challenges ahead. It is also essential to invest in internationalization, exploring new markets and diversifying the client portfolio.

It is imperative that companies invest in research and development in order to offer innovative, quality solutions to customers, while reducing costs and improving the efficiency of delivery times.

Human capital

One of the biggest concerns for companies has been maintaining their most important asset: people. Even with successive economic losses, organizations have focused a lot of attention on preserving their talent, recognizing the importance of employees for long-term success. However, this approach has been a real challenge, requiring efficient management of available resources. It is also important to invest in the development of technical skills and employee training.

The moldmaking industry is constantly evolving and it is essential that professionals are up-to-date and prepared to face the challenges that the future will bring. Continuous training and investment in employee qualifications are determining factors for the success of companies in this sector.

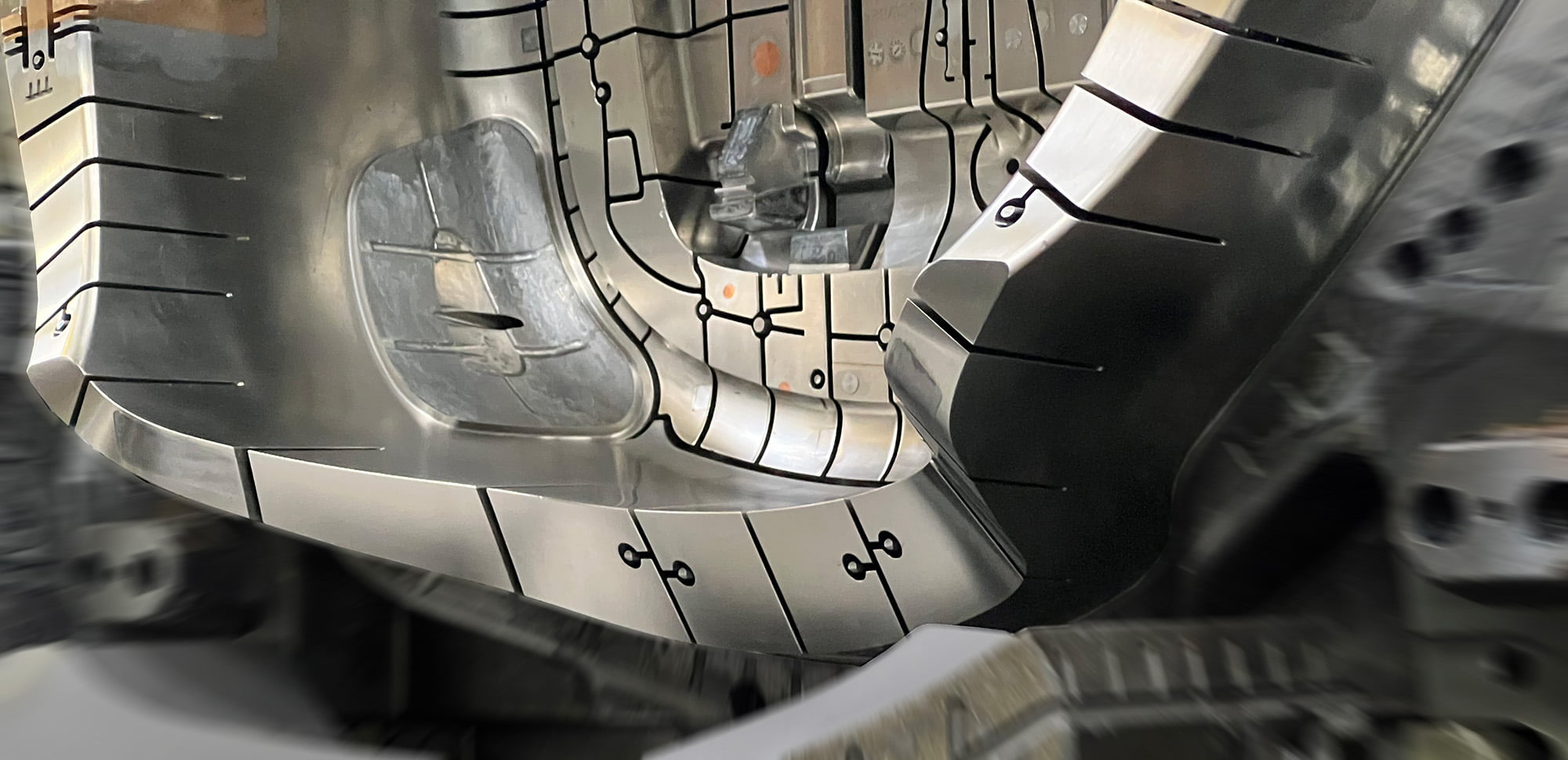

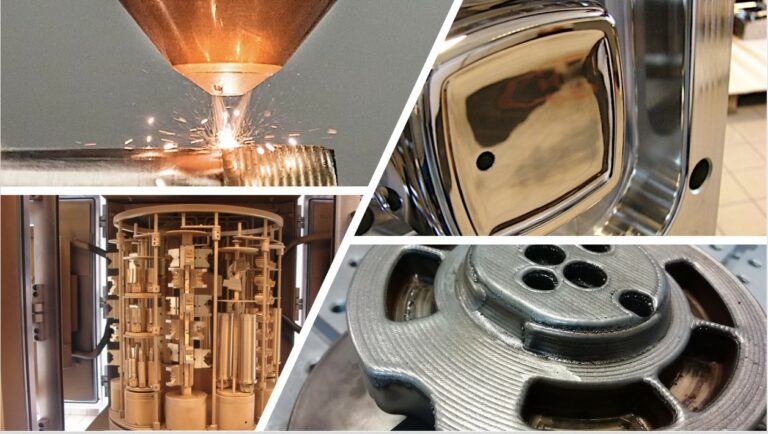

Technology and knowledge generation

For the future, it is crucial that the moldmaking industry is prepared to keep up with changes in the business model. It needs to adopt a proactive stance and carry out a transformation in the management mindset, placing innovation and competitiveness as key elements.

Digitalization and Industry 4.0 play a crucial role in the future of the mouldmaking industry.

The adoption of technologies such as artificial intelligence, the internet of things (IoT) and augmented reality will make it possible to increase the efficiency and quality of production processes, as well as improving collaboration and communication between the different parties involved. The importance of close collaboration between companies in the sector stands out. The creation of strategic partnerships and collaboration on joint projects can boost the competitiveness of the mould industry, allowing knowledge to be shared and resources to be maximized. In addition, it is important to establish an effective dialog between companies, educational and research institutions and government entities.

This collaboration is fundamental to creating the right conditions for the development of the mold industry, promoting research and the development of innovative solutions, and ensuring the long-term sustainability of this sector.

Opinion article: Nuno Siva, Executive Director of Durit Group and President of CENTIMFE - Technological Center for the Mould, Special Tools and Plastics Industry